Industry Challenge

Find an easy way to view rotating equipment data.

The Mittelplate oil field, operated by Wintershall Dea off the coast of Germany, relies on injection pumps to maintain pressure in reservoirs and multiphase pumps to export oil, gas, and water to the Dieksand onshore facility. These pumps are critical rotating equipment that must function smoothly for the production at Germany's largest oil field to operate efficiently.

Unfortunately, Wintershall Dea's maintenance experts lacked an accessible way to view rotating equipment data. Quick access to sensor data trends, equipment status, and key performance indicators could assist them in performing daily analyses, optimizing operations, and avoiding costly repairs.

Solution

Dashboards providing at-a-glance overview of pump operations

Cognite collaborated with Wintershall Dea to extract sensor trends, documents, and data from various systems and consolidate them into a unified, contextualized dataset in Cognite Data Fusion®.

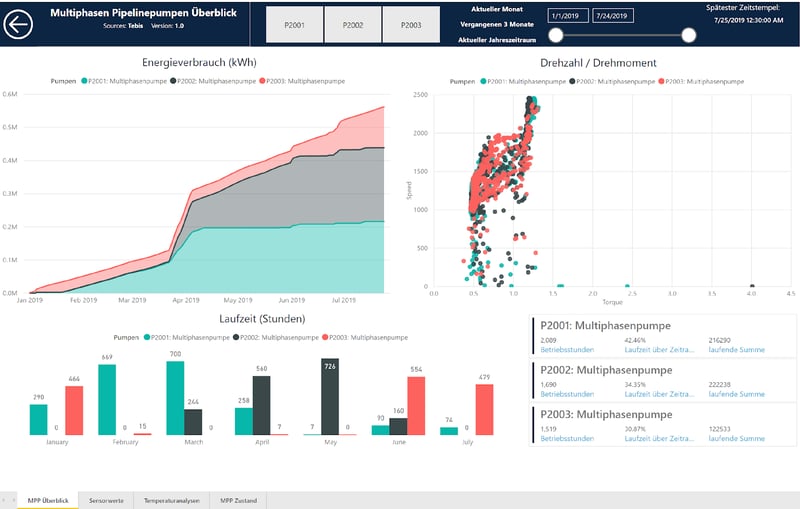

Subsequently, Cognite and Wintershall Dea’s developers then used the contextualized data to build three Power BI dashboards. These dashboards offer maintenance experts a quick and easy overview of pump operations. Users can explore sensor trends, temperatures at critical locations such as bearings, early warnings of deviations from normal operations, and piping and instrumentation diagrams (P&IDs) overlaid with live data from the dashboards' respective landing pages.

Impact

Wintershall Dea’s rotating equipment maintenance experts estimate that the dashboards will help them save 7-10 hours a week by eliminating time that would normally be spent accessing different systems to collect information.

With greater access to data and more time at their disposal, the maintenance experts can optimize Wintershall Dea’s operations for greater throughput, identify maintenance issues before they cause equipment failure, and increase safety at the company’s installations.