Challenge

Provide a holistic overview of maintenance opportunities

Wintershall Dea’s history stretches back more than a century. Today, the company searches for and produces natural gas and crude oil on four different continents.

With so many installations, pipelines, vehicles, and other assets to keep track of, it can sometimes be challenging to take a step back from all the maintenance work going on within the company and analyze larger trends, such as the frequency of issues like corrosion, how often a particular component breaks down, and how much the company is spending on corrective versus preventive maintenance.

Solution

All relevant data in one place

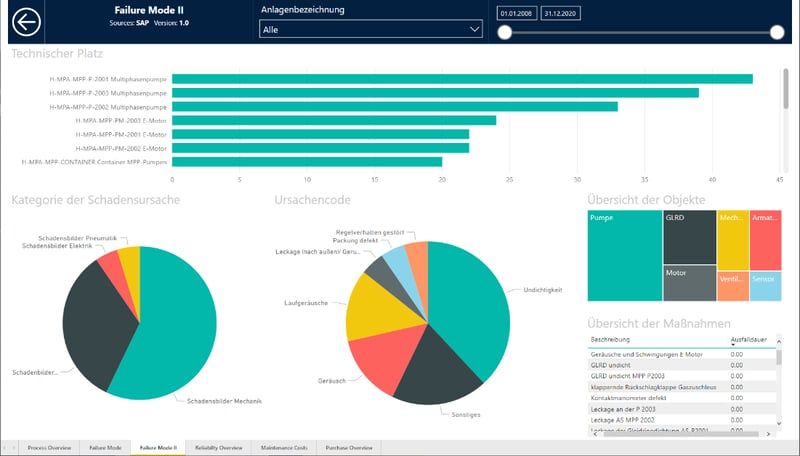

Cognite liberated data about work orders from Wintershall Dea’s computerized maintenance management system, collecting it in Cognite Data Fusion® and visualizing it an easy-to-use Power BI dashboard.

The dashboard aggregates factors that cause equipment failure, reliability metrics, and detailed cost breakdowns, providing a holistic overview of maintenance work at the company’s installations.

Impact

The maintenance dashboard improves Wintershall Dea’s overview of its assets, enabling data-driven decisions about maintenance work.

By analyzing historical maintenance data about the main and subsystems of different installations, the company can more easily draw conclusions about the reliability of its assets, improving its maintenance routines and optimizing production.