Quantafuel, a cleantech company specializing in chemical recycling, is on a mission to create a circular economy for plastic waste by transforming soiled and difficult-to-recycle plastic into new products. Not only does Quantafuel want to solve the world’s plastic waste problem, but they pledge to do so in a sustainable way. To support this mission, Quantafuel uses Cognite Data Fusion® to analyze their chemical recycling process and monitor their operational CO2 emissions in near-real time.

Sustainability needs Industrial DataOps

Quantafuel is building a circular economy for plastic through an energy efficient process that upgrades mixed plastic waste to feedstock for new plastic of virgin quality. At the same time, Quantafuel is building a business model that is green to the core; ensuring all of their plants meet the highest sustainability standards.

However, measuring plant performance and reporting on these high ambitions is a challenge. Quantafuel was unable to find a tool that could break down environmental performance into clear and measurable concepts. They also lacked awareness across the company about the environmental implications of operational decisions and technological solutions.

This is because emissions data sits in a wide variety of repositories and in an even greater variety of formats. Current reporting methods are based on assumptions derived from piecing together excel spreadsheets, PDFs, emails, and more—often hundreds if not thousands of documents. There are some cloud-based reporting systems available on the market, but they still require customers to input much of the data manually. This manual process makes it near impossible to have a real-time, auditable, and traceable picture of plant performance — especially for major industrial players.

Quantafuel needed a solution that not only solved this emissions data problem, but also connected emissions data to production data in a way that would allow their experts to analyze the impact of operational decisions and technological changes so they could balance production and emissions goals and truly optimize operations.

Create a strong data foundation for the entirety of your operation

The data needed to optimize production is actually the same data needed to monitor emissions. This data lives across equipment, systems, plants, the enterprise, and even across vendors. Cognite Data Fusion®, the leading Industrial DataOps platform, consolidates and contextualizes this data, making it easy for Quantafuel`s personnel to explore, visualize, trend, and analyze this data for both production and emissions optimization.

Using Cognite Data Fusion®, Quantafuel developed a data product for sustainability, visualized by a production dashboard to monitor live and historical data from their Frontmatec Scada system. With all of the necessary data now in one place and in one format, Quantafuel can make better use of this data. Quantafuel’s data scientists can use the Python SDK to build models in their preferred computation environment, while domain experts can use the Grafana connectors to easily visualize and analyze the contextualized data, enabling more advanced analytics.

Live data from the SCADA system is continuously ingested and contextualized in Cognite Data Fusion®, giving Quantafuel near-live measurements of key sustainability targets, including amount of plastic recycled, CO2 saved, and resource efficiency of the process (CO2 emitted/ton oil produced).

This near-real-time view of their plant performance allows Quantafuel to optimize production while driving a more efficient production at the same time.

Insights to continually improve production, cost, and sustainability

Cognite Data Fusion® has increased Quantafuel’s understanding of how effective their production process is and of the company’s CO2 footprint. By having accessible and meaningful data, it is easier for Quantafuel to spot gains in resource efficiency and realize where they can also save cost and reduce emissions.

With the insights provided by Cognite Data Fusion®, Quantafuel is able to integrate CO2 effect into budgeting and plant design, helping to achieve its goal of building all future plants to the highest sustainability standards.

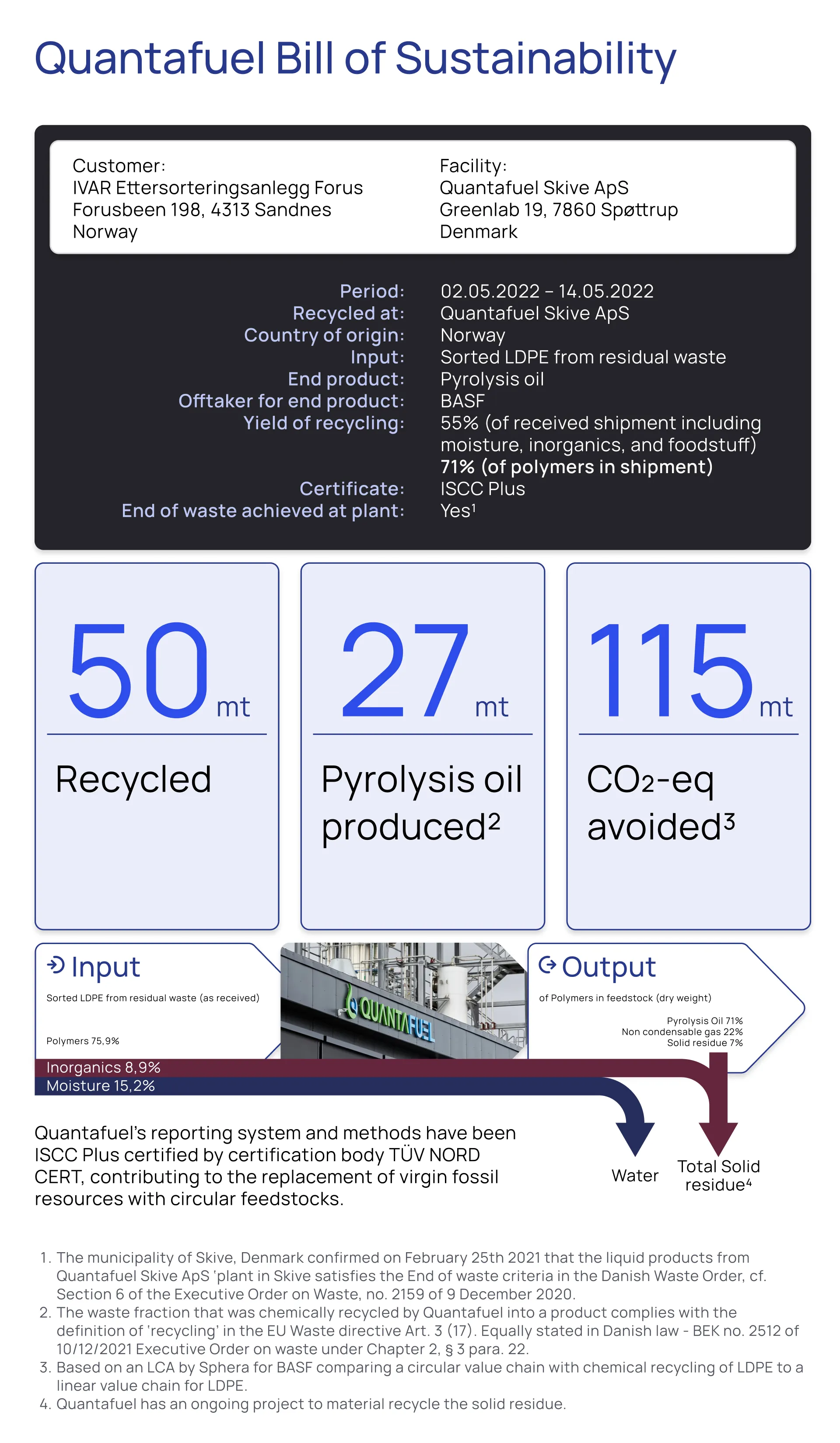

Additionally, Quantafuel can now deliver an innovative “Bill of Sustainability'' for their suppliers. These receipts report on how much plastic waste has been recycled and with what CO2-savings, creating trust and accelerating Quantafuel’s reputation with partners.