Forget hybrid cloud, hybrid analytics is the new black.

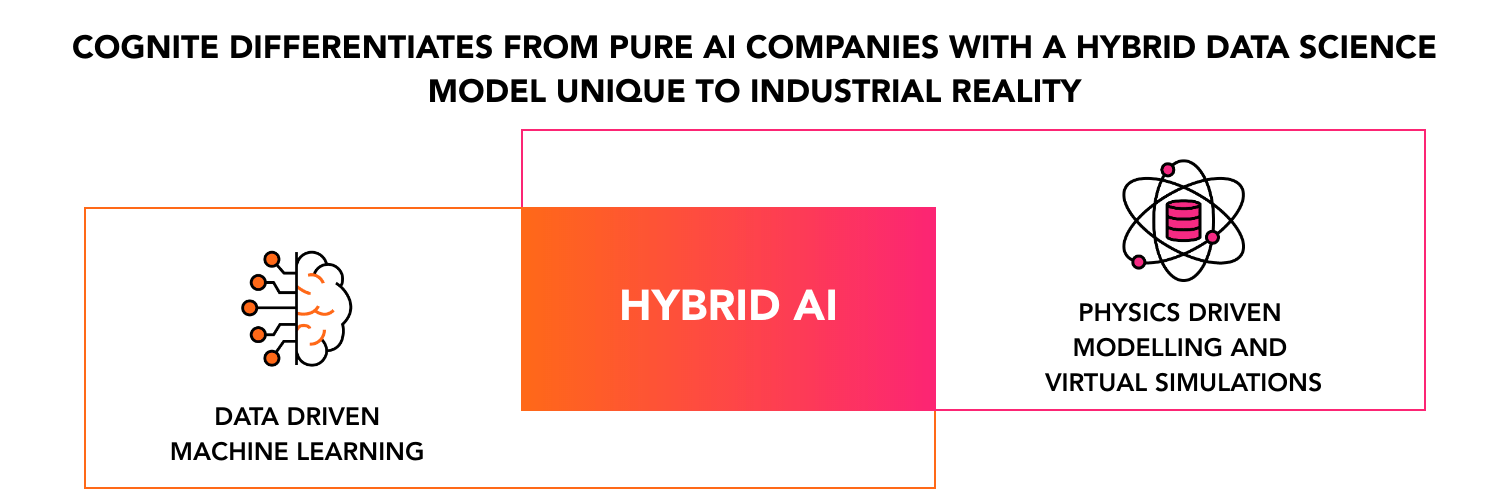

Until recently, purely data-driven artificial intelligence (AI) — machine learning most notably — has been looked upon as the most attractive technology for enabling new data across industries, including digital twins deployed by heavy asset industries such as Oil and Gas. More established, though much less hyped, physics-based modeling has rarely enjoyed the spotlight in recent years.

Read also: Stop searching for subsurface data. Start discovering it

Because of AI’s inherent ‘black box’ nature, however, pure AI-based approaches are failing to gain full acceptance with field operations whose culture is rooted in engineering sciences with zero risk tolerance for critical systems. In addition, mounting empirical evidence from hundreds of proof-of-concepts involving promising AI startups by Oil and Gas industry leaders is debunking the omnipotence of AI to solve production optimization and predictive maintenance use cases as boldly as claimed.

Read also: Reaching a Critical MaaS

This more informed reality of AI in industry is driving the future of hybrid machine learning, a blend of physics and AI analytics that combines the ‘glass box’ interpretability and robust mathematical foundation of physics-based modeling with the scalability and pattern recognition capabilities of AI.

Both physics-based models and machine learning (the most common form of AI applications) can be used to make future predictions — so which one to use for what, and when is a hybrid the best solution?

For systems in the first category, a physics-based model is not possible as we are not able to formulate a robust mathematical model to describe the system. Machine learning, however, does not suffer from the same limitation. In fact, the flip side of AI’s ‘black box’ nature turns it into an advantage here, making it possible to use machine learning also in such scenarios; assuming enough contextualized training data is available. With this condition met, a machine learning model should be able to learn any underlying pattern between the system and its outcomes, and ultimately also make predictions.

.png?width=717&name=Copy%20of%20definition%20(1).png)

Two caveats remain, however. First being the questionable confidence level in resulting predictions (i.e., the precision and recall challenge), possibly rendering an otherwise functioning AI approach unfit for many critical manufacturing processes. Second caveat is the oftentimes absent teaching sample of true failures in critical systems, as traditional scheduled equipment maintenance is designed to prevent such costly failures above all else.

For systems in the second category, a physics-based model can offer a good solution. Physics-based modeling is tried, tested, and validated for even the most critical of simulations — such as space flight orbits — but it too has limitations. The most notable limitation is the computational cost of persisting physics-based models in runtime environments with live data, especially across computationally heavy IoT use cases. It is here where hybrid analytics machine learning is offering an attractive solution.

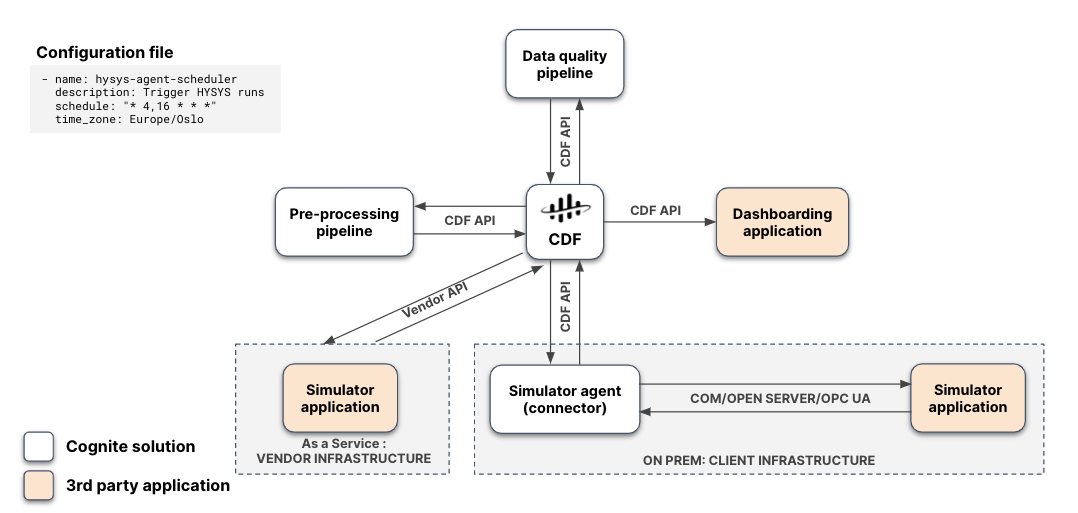

Describing the system in detail using a physics-based model produces physically accurate, rich and fully interpretable synthetic data, such as virtual sensor data and equipment breakpoint data. This data is then used to train a machine learning model for subsequent live operational data analysis in predictive maintenance and production optimization use cases, leveraging the fact that once a machine learning model is trained, using it to make predictions on new data, even large with high velocity, is very efficient.

Second, to give the production algorithm its cognitive edge, such hybrid machine learning models are subject matter expert supervised to truly understand (hence the term ‘cognitive’) the physical boundary conditions of the systems. This greatly enhances the algorithm’s ability to produce meaningful outcomes.

.png?width=1500&name=Ecosystems%20(3).png)

The result is a high confidence tailored hybrid model combining strong domain knowledge (physics) with machine learning for cost efficiency and scalability. Especially in the proliferating space of digital twins, hybrid analytics is showing great potential.

%20of%20Industry%204.0%20(3).png?width=717&name=Copy%20(1)%20of%20Industry%204.0%20(3).png)

Explore the potential of hybrid AI in oil and gas and other process industries, and learn how combining physics with machine learning delivers working AI for industry: