Challenge

Speed up valve testing while maintaining quality

Calendar-based maintenance is an inefficient method of checking the status of equipment, as engineers spend much of their time checking equipment in good working condition.

Process shutdown (PSD) valve testing at the Valhall field in the North Sea used to be time consuming work. First, engineers had to obtain a work permit to access Aker BP’s offshore system. Then, they had to use the system to pull up data on each individual valve, going one by one in the slow system until every valve that was scheduled for maintenance during that session had been checked.

Solution

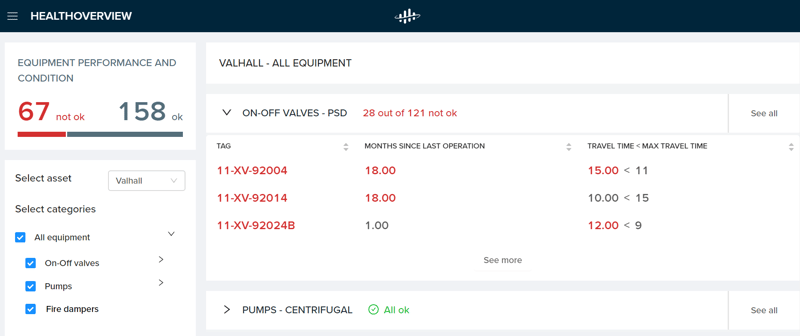

Aker BP used Cognite Data Fusion® to automate and optimize the PSD valve maintenance process at the Valhall field and make data available to engineers on computers, smartphones, and tablets.

Cognite Data Fusion® ingests data from Aker BP’s control system, logging when valves are used and comparing the results to travel time criteria. Engineers can then see an overview of all the valves and generate work orders for valves that don’t meet the set criteria.

The valves can also be displayed in a 3D model of the platform, giving engineers a visual tool for quickly locating different pieces of equipment on the installation.

In the future, Aker BP plans to integrate its computerized maintenance management system (CMMS) with Cognite Data Fusion™, which will enable the company to automatically generate work orders, further reducing the time spent on the administrative side of maintenance.

Impact

The shift toward more automation in maintenance means that engineers no longer have to grapple with a slow offshore system to check each valve manually.

The change is estimated to reduce the number of hours that engineers spend on testing PSD valves a year by about 80 percent. It will also cut the number of annual maintenance checks by two-thirds, and the duration of an average maintenance session in half.

By reducing the time it takes to check safety-critical equipment, Aker BP can reinvest those resources toward maintaining production-critical equipment and performing other important tasks.

-jpg.jpeg?width=910&height=610&name=2%20(1)-jpg.jpeg)